#Real-Time Production Monitoring

Explore tagged Tumblr posts

Text

https://glansa.com/andon/

Discover how Industry Automation in India is revolutionizing manufacturing with smart solutions like Andon systems. Glansa Solutions offers a real-time alert and monitoring system to reduce downtime, improve efficiency, and support Industry 4.0 implementation. Explore how Indian industries are leveraging automation to stay globally competitive.

#Industry Automation in India#Andon System#Manufacturing Automation#Industrial Solutions India#Smart Factory#Glansa Andon#Industry 4.0 India#Real-time Production Monitoring

0 notes

Text

Real-time Production Monitoring | Factracpro

Monitor real time production with advanced product counter data solution Improve performance, plan effectively, and ensure jobs are completed on schedule.

0 notes

Text

Chef WK, lead charcuterie specialist in Alberta Canada

Table of contents

1. Control Program Requirements for Fermented Meat Products

2. Facility and Equipment Requirements

3. Starter Culture

4. Chemical Acidification

5. Water Activity Critical Limits

6. Time and Temperature for Fermented Products

7. Fermentation Done at a Constant Temperature

8. Examples of Degree-hours at constant room temperatures

9. Fermentation Done at Different Temperatures

10. Fermentation done at Different temperatures

11. What happens if fermentation fails to hit critical limit?

12. E. coli and Salmonella Control in Fermented Sausages

13. Options for E. coli validation

14. Option1; Heating

15. Option 2; pH, heating, holding, diameter

16. Safety and consistency

Control Program Requirements for Fermented Meat Products

The producer must have a program in place to assess the incoming product. This program should outline specifications for the incoming ingredients. This may include criteria including receiving temperature, farm/ supplier, lot code or packed on date, species/cut etc.

2. Facility and Equipment Requirements

Equipment used in the fermentation process must be included in the operator's prerequisite control programs. These must include the following elements:

Temperature in the fermentation, drying and smoking chambers must be uniform and controlled to prevent any fluctuation that could impact on the safety of the final product.

Fermentation, drying and smoking chambers must be equipped with a shatter resistant indicating thermometer, (or equivalent), with graduations of 1°C or less. If mercury thermometers are used, their mercury columns must be free from separations. All thermometers must be located such that they can be easily read.

Fermentation and smoking chambers must be equipped with a recording thermometer for determining degree-hours calculations in a reliable manner. Recording thermometers are also preferable in drying and aging rooms but, in these rooms, it may be sufficient to read and record the temperatures 2 times a day.

Drying and aging rooms must be equipped with humidity recorders in order to prevent uncontrolled fluctuations of the relative humidity. The only alternative to an automatic humidity recorder in these rooms would be for the company to manually monitor and record ambient humidity twice a day (morning and afternoon) every day with a properly calibrated portable humidity recorder.

For routine monitoring, accurate measurement electronic pH meters (± 0.05 units) should be employed. It is important that the manufacturer's instructions for use, maintenance and calibration of the instrument as well as recommended sample preparation and testing be followed.

When the aw of a product is a critical limit set out in the HACCP plan for a meat product, accurate measurement devices must be employed. It is important that the manufacturer's instructions for use, maintenance and calibration of the instrument be followed.

3. Starter Culture

The operator must use a CFIA approved starter culture. This includes Freeze-dried commercially available culture as well as back-slopping (use of previously successful fermented meat used to inoculate a new batch). When performing back-slopping, the operator must have a control program in place to prevent the transmission of pathogens from when using the inoculum from a previous batch to initiate the fermentation process of a new batch. These must include:

The storage temperature must be maintained at 4°C or less and a pH of 5.3 or less.

Samples for microbiological analysis must be taken to ensure that the process is in line with the specifications.

The frequency of sampling is to be adjusted according to compliance to specifications.

Any batch of inoculum which has a pH greater than 5.3 must be analysed to detect at least Staphylococcus aureus. Only upon satisfactory results will this inoculum be permitted for use in back slopping.

This can be an expensive and a time exhaustive process and is generally avoided due to food safety concerns. AHS does not allow back-slopping.

[Chef WK was in communication with the U of A to get his method, a starter mix, studied.]

4. Chemical Acidification

If product is chemically acidified by addition of citric acid, glucono-delta-lactone or another chemical agent approved for this purpose, controls must be in place and records kept to ensure that a pH of 5.3 or lower is achieved by the end of the fermentation process. These acids are encapsulated in different coatings that melt at specific temperatures, which then release the powdered acids into the meat batter and directly chemically acidulate the protein.

Summer sausage is a very common chemically acidified product. The flavor profile tends to be monotone and lacking depth.

5. Water Activity Critical Limits

The aw may be reduced by adding solutes (salt, sugar) or removing moisture.

Approximate minimum levels of aw (if considered alone) for the growth of:

molds: 0.61 to 0.96

yeasts: 0.62 to 0.90

bacteria: 0.86 to 0.97

Clostridium botulinum: 0.95 to 0.97

Clostridium perfringens: 0.95

Enterobacteriaceae: 0.94 to 0.97

Pseudomonas fluorescens: 0.97

Salmonella: 0.92 - 0.95

Staphylococcus aureus: 0.86

parasites: Trichinella spiralis will survive at an aw of 0.93 but is destroyed at an aw of 0.85 or less.

The above levels are based on the absence of other inhibitory effects such as nitrite, competitive growth, sub-optimum temperatures, etc., which may be present in meat products. In normal conditions, Staphylococcus aureus enterotoxins are not produced below aw 0.86, although in vacuum packed products this is unlikely below aw 0.89.

6. Time and Temperature for Fermented Products

Certain strains of the bacteria Staphylococcus aureus are capable of producing a highly heat stable toxin that causes illness in humans. Above a critical temperature of 15.6°C, Staphylococcus aureus multiplication and toxin production can take place. Once a pH of 5.3 is reached, Staphylococcus aureus multiplication and toxin production are stopped.

Degree-hours are the product of time as measured in hours at a particular temperature multiplied by the "degrees" measured in excess of 15.6°C (the critical temperature for growth of Staphylococcus aureus). Degree-hours are calculated for each temperature used in the process. The limitation of the number of degree-hours depends upon the highest temperature in the fermentation process prior to the time that a pH of 5.3 or less is attained.

The operator is encouraged to measure temperatures at the surface of the product. Where this is not possible, the operator should utilize fermentation room temperatures. The degree hour calculations are based on fermentation room temperatures. Temperature and humidity should be uniform throughout the fermentation room.

A process can be judged as acceptable provided the product consistently reaches a pH of 5.3 using:

fewer than 665 degree-hours when the highest fermentation temperature is less than 33°C;

fewer than 555 degree-hours when the highest fermentation temperature is between 33° and 37°C; and

fewer than 500 degree-hours when the highest fermentation temperature is greater than 37°C.

This means that as the temperature increases, the amount of time that you have available to reach 5.3 or under is shorter. The warmer the temperature, the sharper the log growth phase of bacteria, which equates to more overshoot in lactic acid production, faster.

8. Examples of Degree-hours at constant room temperatures

Example 1:

Fermentation room temperature is a constant 26°C. It takes 55 hours for the pH to reach 5.3.

Degrees above 15.6°C: 26°C - 15.6°C = 10.4°C Hours to reach pH of 5.3: 55 Degree-hours calculation: (10.4°C) x (55) = 572 degree-hours

The corresponding degree-hours limit (less than 33°C) is 665 degree-hours.

Conclusion: Example 1 meets the guideline because its degree-hours are less than the limit.

Example 2:

Fermentation room temperature is a constant 35°C. It takes 40 hours for the pH to reach 5.3.

Degrees above 15.6°C: 35°C - 15.6°C = 19.4°C Hours to reach pH of 5.3: 40 Degree-hours calculation: (19.4°C) x (40) = 776 degree-hours

The corresponding degree-hours limit (between 33 and 37°C) is 555 degree-hours.

Conclusion: Example 2 does not meet the guideline because its degree-hours exceed the limit

9. Fermentation Done at Different Temperatures

When the fermentation takes place at various temperatures, each temperature step in the process is analyzed for the number of degree-hours it contributes. The degree-hours limit for the entire fermentation process is based on the highest temperature reached during fermentation.

Example 1:

It takes 35 hours for product to reach a pH of 5.3 or less. Fermentation room temperature is 24°C for the first 10 hours, 30°C for second 10 hours and 35°C for the final 15 hours.

Step 1

Degrees above 15.6°C: 24°C - 15.6°C = 8.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (8.4°C) x (10) = 84 degree-hours

Step 2

Degrees above 15.6°C: 30°C - 15.6°C = 14.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (14.4°C) x (10) = 144 degree-hours

Step 3

Degrees above 15.6°C: 35°C - 15.6°C = 19.4°C Hours to reach pH of 5.3: 15 Degree-hours calculation: (19.4°C) x (15) = 291 degree-hours

Degree-hours calculation for the entire fermentation process = 84 + 144 + 291 = 519

The highest temperature reached = 35°C

The corresponding degree-hour limit = 555 (between 33°C and 37°C)Conclusion: Example 1 meets the guideline because its degree-hours are less than the limit.

10. Fermentation done at Different temperatures

Example 2:

It takes 38 hours for product to reach a pH of 5.3 or less. Fermentation room temperature is 24°C for the first 10 hours, 30°C for the second 10 hours and 37°C for the final 18 hours.

Step 1

Degrees above 15.6°C: 24°C - 15.6°C = 8.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (8.4°C) x (10) = 84 degree-hours

Step 2

Degrees above 15.6°C: 30°C - 15.6°C = 14.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (14.4°C) x (10) = 144 degree-hours

Step 3

Degrees above 15.6°C: 37°C - 15.6°C = 21.4°C Hours to reach pH of 5.3: 18 Degree-hours calculation: (21.4°C) x (18) = 385.2 degree-hours

Degree-hours calculation for the entire fermentation process = 84 + 144 + 385.2 = 613.2

The highest temperature reached = 37°C

The corresponding degree-hour limit = 555 (between 33°C and 37°C)

Conclusion: Example 2 does not meet the guidelines because its degree-hours exceed the limit.

11. What happens if fermentation fails to hit critical limit?

What happens if the batch takes longer than degree-hours allows? For restaurant level production, it's always safer to discard the product. The toxin that Staph. Aureus produces is heat stable and cannot be cooked to deactivate. In large facilities that produce substantial batches, the operator must notify the CFIA of each case where degree-hours limits have been exceeded. Such lots must be held and samples of product submitted for microbiological laboratory examination after the drying period has been completed. Analyses should be done for Staphylococcus aureus and its enterotoxin, and for principal pathogens, such as E. coli O157:H7, Salmonella, and Clostridium botulinum and Listeria monocytogenes.

If the bacteriological evaluation proves that there are fewer than 104 Staphylococcus aureus per gram and that no enterotoxin or other pathogens are detected, then the product may be sold provided that it is labelled as requiring refrigeration.

In the case of a Staphylococcus aureus level higher than 104 per gram with no enterotoxin present the product may be used in the production of a cooked product but only if the heating process achieves full lethality applicable to the meat product.

In the case where Staphylococcus aureus enterotoxin is detected in the product the product must be destroyed.

12. E. coli and Salmonella Control in Fermented Sausages

Business' that manufacture fermented sausages are required to control for verotoxinogenic E. coli including E. coli O157:H7 and Salmonella when they make this type of product. This includes:

establishments which use beef as an ingredient in a dry or semi-dry fermented meat sausage;

establishments which store or handle uncooked beef on site;

Establishments which do not use beef and do not obtain meat ingredients from establishments which handle beef are not currently required to use one of the five options for the control of E. coli O157:H7 in dry/semi-dry fermented sausages.

Any processed RTE product containing beef or processed in a facility that also processed beef, must be subjected to a heat treatment step to control E. coli O157:H7. Heating to an internal temperature of 71°C for 15 seconds or other treatment to achieve a 5D reduction is necessary. This is a CFIA requirement and is not negotiable.

Uncooked air dried products produced as RTE, must meet shelf stable requirements as detailed for Fermented-Dry products.

13. Options for E. coli validation

Without lab testing, the two main methods of validation are with heat treating by either low temp and a long duration, or various hotter processing temperatures for a shorter timeframe.

A challenge study to validate a process can take 1 year and over $100,000!

14. Option1; Heating

15. Option 2; pH, heating, holding, diameter

16. Safety and consistency

The aw and pH values are critical in the control of pathogens as well as to ensure shelf-stability in all semi-dry and dry fermented meat products. Each batch must be tested for aw and/or pH in order to verify that the critical limits are met.

Although aw measurement is mandatory only for shelf stable products, it is strongly recommended that the producer determine the aw values achieved for each product type they manufacture and for each product. Once this has been established, frequent regular checks should be made to ensure consistency. In the U.S., they rely on moisture to protein ratio and have set targets. This lab-tested value is a direct correlation of the % water to % meat protein and not aw. This gives more consistency to common names. For example, to legally call a product "jerky" it must have a MPR of 0.75:1 or lower. Remember your ABCs:

Always be compliant.

-AND-

Documentation or it didn't happen.

(tags)

Charcuterie,Fermented Meat,Food Safety,Starter Culture,Chemical Acidification,Water Activity,Fermentation Process,Degree-Hours Method,Foodborne Pathogens,Meat Processing Guidelines,Chef WK Alberta Canada,Food Industry Standards,pH Critical Limits,Thermal Processing,Food Preservation,Food Microbiology,Sausage Fermentation,Charcuterie Expertise,Fermented Meats ,Food Safety Standards,Food Processing Guidelines,Starter Cultures,Chemical Acidification,Water Activity (a_w),Critical Limits,Degree-Hours Method,Foodborne Pathogens,Meat Processing Equipment,Processing Facility Requirements,Hazard Analysis and Critical Control Points (HACCP),Food Preservation Techniques,Temperature Control,Pathogen Reduction,Food Industry Compliance,Documentation Practices,Heat Treatment,pH Control,Food Stability,Consistency in Production,Microbial Testing,Real-time Monitoring,Process Validation,Regulatory Requirements,Verotoxigenic E. coli,Lethality Standards,Product Labelling,Spoilage Prevention,Enterotoxin Detection,Shelf-Stable Products,Moisture to Protein Ratio (MPR)

#Charcuterie#Fermented Meat#Food Safety#Starter Culture#Chemical Acidification#Water Activity#Fermentation Process#Degree-Hours#Meat Processing Guidelines#Thermal Processing#Food Preservation#Food Microbiology#Sausage Fermentation#Starter Cultures#Critical Limits#Meat Processing#Food Preservation Techniques#Temperature Control#Pathogen Reduction#Food Industry#Heat Treatment#pH Control#Food Stability#Microbial Testing#Real-time Monitoring#Process Validation#Spoilage Prevention#Enterotoxin Detection#Shelf-Stable Products#Moisture to Protein Ratio (MPR)

3 notes

·

View notes

Text

Unlocking the Future of Manufacturing: AI Innovation Panel with Certivo & Industry Leaders

Join Certivo at "Manufacturing Reimagined: AI-Powered Innovation" — a dynamic panel event exploring how AI is transforming the manufacturing value chain. Discover how automation and intelligent compliance can accelerate product launches and reduce regulatory delays. Hear from industry pioneers including Certivo CEO Kunal Chopra, T.A. McCann (PSL), and Vineet Thuvara (Fluke). Hosted by AAIA Seattle, PSL, and K&L Gates. 📅 May 20, 2025 | 3:30–5:30 PM | Downtown Seattle Reserve your seat now: https://lu.ma/o9h7ds6s Learn more about our AI solutions at certivo.com

#AI-powered compliance solutions for manufacturing#automate product compliance in manufacturing#AI tools to reduce regulatory delays#AI-driven product launch acceleration#intelligent compliance software for R&D teams#streamline manufacturing compliance with AI#real-time regulatory monitoring platform#AI-based risk management in manufacturing#enterprise AI solutions for global product launch#manufacturing innovation event Seattle 2025

0 notes

Text

What's on your mind about Home Security Cameras?

What’s on your mind about home security cameras? I’ve been exploring various brands, and their real-time tracking cameras are impressive! They offer seamless monitoring and enhance peace of mind at home. Have you tried any home security products? Share your experiences or post pictures of your setup!

Sent from my device using Home Security Hub.

#home security cameras#real-time tracking#monitoring#peace of mind#home security products#user experiences#setup

0 notes

Text

Exploring the Benefits of the App-Controlled Breast Pump from Momcozy

The maternal and baby products industry has seen remarkable innovations, and one standout is the app-controlled breast pump from Momcozy. This cutting-edge device offers convenience and efficiency for breastfeeding mothers, allowing them to control pumping sessions directly from their smartphones.

With features like customizable settings and real-time monitoring, the Momcozy app-controlled breast pump ensures a comfortable experience tailored to each individual's needs. It promotes a positive breastfeeding journey by making it easier for mothers to manage their time and milk supply effectively.

Many users have shared their positive experiences, highlighting how this technology has simplified their daily routines. The ability to track pumping sessions and adjust settings on the go empowers mothers, making breastfeeding a more enjoyable and stress-free experience.

Overall, the Momcozy app-controlled breast pump is a fantastic addition to the maternal and baby products market, combining innovation with practicality to support mothers.

#technology#app-controlled breast pump#real-time monitoring#milk supply#maternal products#breastfeeding#Momcozy

0 notes

Text

Embracing the Future of Maternal and Baby Products with Momcozy!

Hello everyone! I'm excited to share my thoughts on the wonderful world of maternal and baby products, specifically focusing on the amazing brand Momcozy and their innovative babycozy monitor.

As a parent, finding the right products that prioritize both comfort and safety for our little ones is essential. Momcozy has truly stepped up to the plate, offering a range of high-quality items designed to make parenting easier and more enjoyable. Their babycozy monitor is a standout product, providing peace of mind to parents by ensuring they can keep an eye on their baby at all times.

The babycozy monitor features advanced technology that allows for real-time monitoring, ensuring that you can see and hear your baby from anywhere in your home. This means you can go about your day, whether it's cooking, cleaning, or working, while still being connected to your little one. The clarity of the video and sound is impressive, making it easy to check in without any worries.

Moreover, Momcozy is dedicated to making parenting a more joyful experience. Their products are not only functional but also stylish, allowing parents to feel good about the items they choose for their children. It's refreshing to see a brand that understands the needs of modern parents and creates products that truly enhance our lives.

In conclusion, if you're looking for reliable and stylish maternal and baby products, I highly recommend checking out Momcozy and their babycozy monitor. It's a fantastic investment in your child's safety and your peace of mind. Let's celebrate the positive strides in the maternal and baby products industry together!

Looking forward to hearing your thoughts and experiences with Momcozy products!

0 notes

Text

Exploring the Future of Smart Homes with Dreame

Hello everyone! I'm excited to share my thoughts on the amazing innovations in the smart home industry, particularly focusing on Dreame's incredible cleaning brush scrubber.

Dreame has truly revolutionized the way we think about home cleaning. Their cleaning brush scrubber is designed to make our lives easier by effectively tackling dirt and grime with minimal effort. The ergonomic design and powerful cleaning capabilities ensure that every corner of your home can sparkle like never before.

What's even more impressive is how Dreame integrates smart technology into their products. With features like app control and real-time monitoring, you can manage your cleaning tasks from anywhere, making home maintenance more convenient and efficient.

If you are looking to enhance your cleaning routine and embrace the future of smart homes, I highly recommend checking out Dreame's innovative products. Together, we can create cleaner and smarter living spaces!

0 notes

Text

Streamlined Time and Attendance Management for Enhanced Workforce Efficiency

Effective time and attendance management is crucial for maintaining workforce productivity and compliance. Advanced systems leverage technology like biometric devices, mobile apps, and cloud-based platforms to track employee work hours accurately. These tools provide real-time data on attendance, overtime, and leave, ensuring seamless payroll integration and better workforce planning. Businesses can minimize errors, enhance efficiency, and focus on strategic growth by automating attendance processes.

More info: https://ahalts.com/solutions/hr-services/outsourcing-time-attendance

#Time and Attendance Management#Biometric Attendance#Employee Time Tracking#Attendance Software#Workforce Productivity#Leave Management#Work Hours Monitoring#Automated Attendance System#Real-Time Tracking#HR Solutions

0 notes

Text

Real-Time Employee Monitoring: How Instant Insights are Changing the Workplace

Monitoring employees in real time has perhaps never been in as much demand today with all the changes happening in the workplace. Increasingly, employers embrace solutions for real-time tracking of employees’ work in order to enhance productivity, make people more accountable, and elevate the level of transparency in their endeavors. The tools provide the employer with real-time insights into how a team is performing at any given time, which is easier to deploy to areas of improvement, thus leading to a more productive kind of culture.

But as with any workplace technology, implementing real-time employee monitoring involves opportunities and challenges. This article focuses on what real-time employee monitoring is, how it works, its benefits, and what the ethical implications are for companies to deliberate before using these tools.

Understanding real-time employee monitoring

Real-time employee monitoring software involves tools that can track the activities and productivity of the employees in real-time. Real-time monitoring solutions differ from traditional monitoring methods since they offer periodic feedback on how well the employees are performing, such as how much time was spent on the task, which applications and websites were used, and even their overall productivity levels.

The most important feature of real-time work tracking solutions is the ability to collect data, process it, and present the information in real time. This enables the managers to make the proper decisions with regard to workforce management without waiting for a day’s, week’s, or month’s end conclusion about performance. Be they in the office or working remotely, real-time employee monitoring informs operations how effectively teams are working.

How can companies implement real-time monitoring?

Implementation of real-time employee monitoring in a company requires many steps to be followed with precision to ensure a smooth integration and success. Here’s how businesses can make use of it:

Select Right Software: First of all, choose real-time employee monitoring software fitting the requirements and needs of your organization. This may even depend on ease of use, scalability, integration with already existing tools, and price. Handdy has been one of the most reasonable solutions since it starts with a pricing structure at $0.99 per user.

Define Monitoring Criteria: Identify what activities are to be monitored and why. It might include an activity such as time spent on specific tasks, the applications used, or websites visited.

Communicate with Employees: Monitoring software implementation must necessarily be transparent. The system, its purpose, and the benefits toward the company must be discussed with employees. Communication in ways like this helps indicate a sense of trust in employees in question and reduces resistance to this new system.

Train managers and employees: Train the managers and employees how to effectively use the software so that they do not misuse it. The data interpretation, goal-setting about the performances, and its utilization should be taught for continuous improvement.

Monitor and change: Once the system is in place, continuously monitor how it’s working. Gather feedback from employees and managers. Then change criteria or features if needed in order to promote productivity and ensure that the software is doing what it should be doing.

The advantages of real-time tracking to the employer

Real-time employee monitoring has an abundance of benefits for employers who wish either to boost productivity or trim costs through the streamlining of operations:

Improved Productivity: Immediate feedback on the usage of an employee’s time informs which activities are inefficient and how they could better make use of their time. Managers can advise on staying focused or modify workloads in real-time to avoid burnout or downtime.

Better Resource Allocation: With the help of such data concerning the activities of the employees, managers can make resource allocation by basing it on data. For example, a department might be overburdened with too many tasks while the other department is underutilized. Workloads can be adjusted so that distributions are balanced.

Improved Accountability: Real-time monitoring fosters accountability by involving employees in understanding their own performance. Once the employee knows that he is monitored, it is more likely that he will get back on track, thus contributing to the success of the whole company.

Enhanced Remote Work Management: With more and more employees working remotely, real-time monitoring software has come to be very important to ensure that teams are always connected and productive. Managers can easily monitor the progress of their remote workforce and understand challenges before they grow.

Data-Driven Decision Making: Real-time monitoring will provide managers with precise data on employee performance, so decisions in hiring, training, promotion, and other HR-related processes will be much more informed.

Employee Monitoring

Enhancing Workplace Productivity: A Comprehensive Guide to Boosting Team Accountability

Privacy concerns and ethical matters in employee monitoring

Real-time employee monitoring has several benefits but poses some very important issues with regard to privacy concerns and other ethical matters that employers must address. In a healthy work environment, there needs to be a balance between getting productivity and preserving privacy.

Employee Consent: Employees need to be informed before the deployment of monitoring software. The employees ought to know what data will be tracked, why it is being tracked, and how it is used. Employees should feel respect for their privacy even though they are monitored.

Transparency: Transparency in how monitoring data is used is key to building trust with employees. Employers should openly explain the objectives of real-time monitoring and how it contributes to the company’s success. This helps employees see the value in the system and reduces the risk of resentment or disengagement.

Employee Perspective: How real-time monitoring affects work culture

Real-time monitoring might provide more accountability, as well as increased productivity, but the question arises as to the staff attitude and reaction to these methods. In general, a staff may feel more engaged and motivated when their individual effort is going to be reflected in real-time feedback. However, without proper communication, monitoring can be seen as invasive and lead to a decrease in job satisfaction.

In establishing a positive work culture, employers must instill in their employees the message that the goal of monitoring is to help them, not punish them.

Conclusion

Employee monitoring in real time is undoubtedly changing the complexion of the workplace because this will make it possible for employers to identify an employee’s performance at a glance. While providing numerous advantages, such as increased productivity, productive usage of resources, and successful management of remote work, employers should have it in a way that is transparent and respectful of privacy. If done ethically and with strategic thought, companies will discover that they are building an effective, responsible, responsive workforce.

Incorporating real-time work tracking solutions, such as Handdy, allows businesses to stay ahead of the curve. Cultivation of a workplace culture that mines value from concepts such as transparency, efficiency, and growth.

#employee monitoring#productivity monitoring#productivity tracking#real time monitoring#real time tracking solutions#employee monitoring software

0 notes

Text

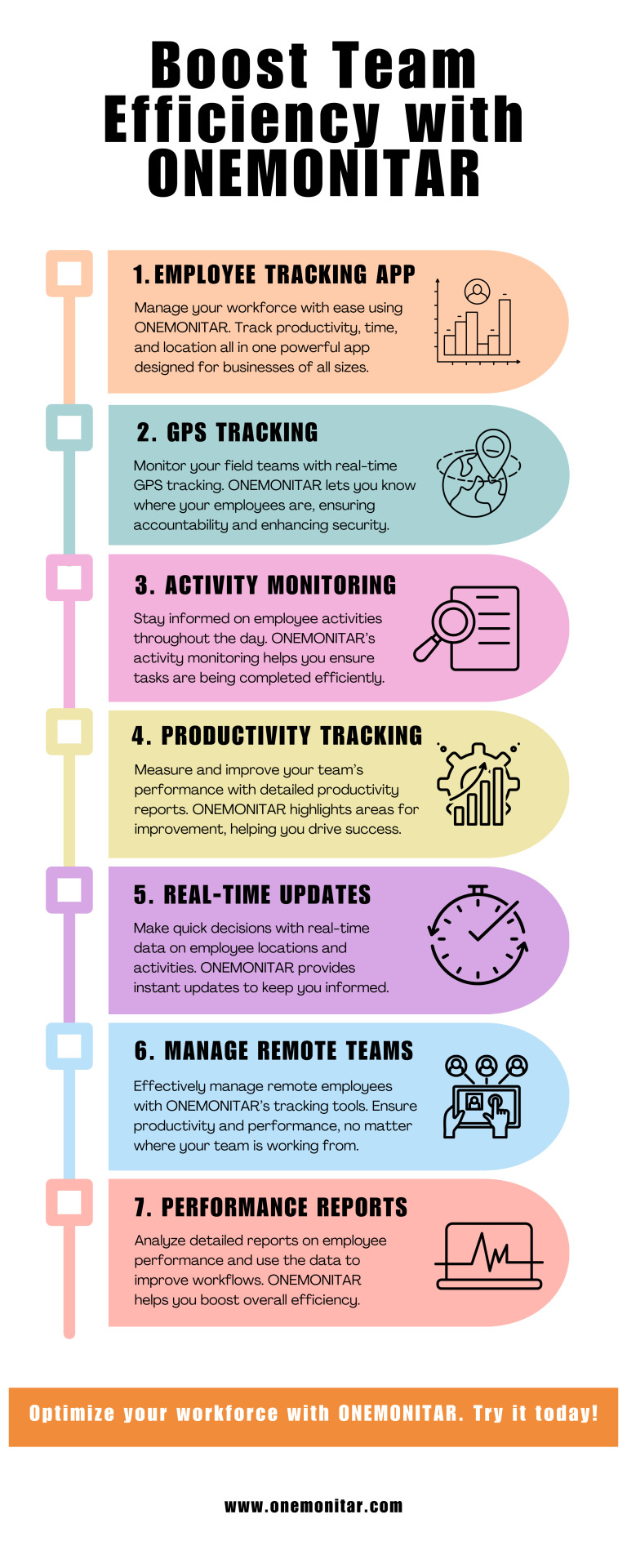

Boost Team Efficiency with ONEMONITAR

Looking for an efficient way to manage your team and boost productivity? Check out ONEMONITAR's employee tracking app infographic! Discover how you can easily track employee activities, monitor GPS locations, and get real-time updates—all from one app. Whether you're managing a remote team or need detailed performance reports, ONEMONITAR helps you stay on top of your workforce and improve results.

Boost your business performance today with ONEMONITAR!

#Best employee tracking app#Employee monitoring software#GPS employee tracking app#Employee activity monitoring app#Employee productivity tracking app#Employee tracking app for Android#Remote employee tracking app#Real-time employee tracking app#Employee location tracking app#Employee tracking software for small business#Employee performance tracking app#Mobile employee tracking app

0 notes

Text

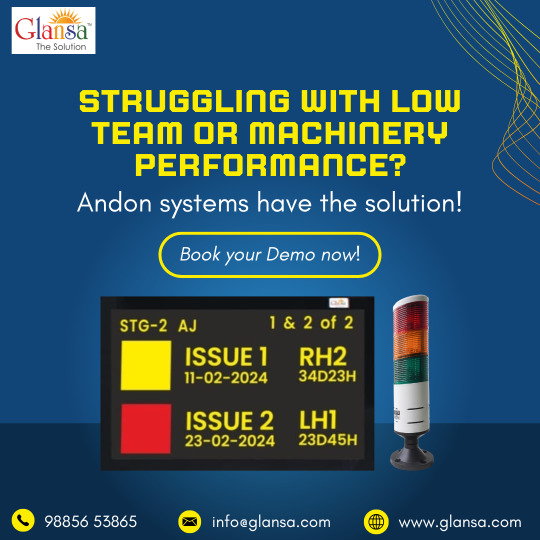

Glansa Solutions specializes in smart factory technologies, including advanced Andon devices for real-time production monitoring. Our customizable Andon systems help manufacturers reduce downtime, improve shop floor communication, and support lean manufacturing processes. Trusted by industries like automotive, electronics, and FMCG.

#Andon Device#Glansa Solutions#Lean Manufacturing Tools#Industrial Automation#Smart Factory Systems#Shop Floor Monitoring#Real-Time Alert System#Production Efficiency

0 notes

Text

Real-time Production Monitoring | Factracpro

FactracPro offers cutting-edge real-time production monitoring solutions designed to optimize manufacturing efficiency and improve operational transparency. Our platform provides instant access to critical production data, empowering businesses to track performance, identify bottlenecks, and boost productivity with actionable insights. With FactracPro, stay ahead of your production goals and make informed decisions backed by reliable, real-time metrics. Transform your operations today with FactracPro!

0 notes

Text

Video Autogenerated by Faceless.Video

Micro AI is revolutionizing the way we interact with technology.

Micro AI is transforming our interaction with technology by providing lightweight, hyper-efficient models tailored for Edge devices such as smartwatches, IoT sensors, drones, and home appliances. This cutting-edge innovation facilitates real-time data processing and decision-making directly on the device, eliminating reliance on constant cloud connectivity. Imagine your smartwatch instantly analyzing health data or your smart home system making immediate adjustments based on real-time inputs—all thanks to micro AI. One of the key benefits of micro AI lies in its low latency and local processing capabilities. In industrial automation, it can monitor machinery in real time to predict failures before they occur. For smart homes, it enhances convenience and security by allowing appliances to learn from user behavior while optimizing energy consumption. In healthcare, wearable devices equipped with micro AI can provide critical monitoring of vital signs and alert medical professionals during emergencies—ensuring timely interventions that could save lives.

#microai #EdgeComputing

#neturbiz#micro AI#AI technology#Edge devices#SmartWatches#IoT sensors#drones#home appliances#real-time data#local processing#low latency#industrial automation#smart homes#healthcare technology#productivity enhancement#energy efficiency#wearable devices#health monitoring#smart thermostat#security systems#user behavior#machine monitoring#predictive maintenance#autonomous appliances#emergency alerts#continuous monitoring#technology revolution#intelligent systems#operational costs#data processing

0 notes

Text

Boost your productivity tracking software with Workstatus! Our advanced analytics feature provides in-depth insights into your team's performance, helping you identify trends, optimize workflows, and enhance overall efficiency. With Workstatus, you can turn data into actionable strategies, ensuring your team stays on track and productive.

#productivity tracking software#employee performance#team efficiency#productivity tools#real-time monitoring

0 notes

Text

Unlocking Efficiency & Growth: A Guide to Oracle Integration Cloud Services

In today’s time, businesses are constantly seeking ways to optimize their operations and drive growth. One solution that has emerged as a game-changer is Oracle Integration Cloud Services (ICS). This comprehensive platform offers a wide range of tools and capabilities designed to streamline processes, integrate applications, and unlock efficiency across the organization. In this guide, we’ll delve into the intricacies of Oracle ICS, exploring its features, benefits, and how it can empower businesses to achieve their goals.

Understanding Oracle Integration Cloud Services

At its core, Oracle ICS is a cloud-based integration platform that enables seamless connectivity between various applications, systems, and data sources. Whether it’s connecting on-premises applications with cloud-based solutions or integrating disparate systems within the organization, Oracle ICS provides the flexibility and scalability needed to simplify complex integration challenges.

Key Features and Capabilities

Oracle ICS offers a plethora of features and capabilities designed to streamline integration processes and drive efficiency. Some key highlights include:

1. Drag-and-Drop Integration:

With an intuitive drag-and-drop interface, users can easily create and configure integrations without the need for extensive coding or technical expertise.

2. Prebuilt Integrations:

Oracle ICS comes with a library of prebuilt integrations for popular applications and services, allowing businesses to quickly connect their systems and accelerate time to value.

3. Real-Time Monitoring:

The platform provides real-time monitoring and analytics capabilities, giving users visibility into the performance of their integrations and enabling proactive problem-solving.

4. Robust Security:

Oracle ICS prioritizes security and compliance, with built-in encryption, access controls, and data protection features to safeguard sensitive information.

Benefits of Oracle Integration Cloud Services

The adoption of Oracle ICS offers numerous benefits for businesses looking to optimize their operations and drive growth:

1. Improved Efficiency:

By streamlining integration processes and automating repetitive tasks, Oracle ICS helps businesses reduce manual effort and increase productivity.

2. Enhanced Agility:

With its flexible architecture and scalability, Oracle ICS enables businesses to adapt quickly to changing market conditions and customer demands.

3. Cost Savings:

By eliminating the need for costly custom integrations and reducing reliance on IT resources, Oracle ICS helps businesses lower their overall integration costs.

4. Accelerated Innovation:

With faster time to market for new initiatives and the ability to quickly test and iterate on ideas, Oracle ICS empowers businesses to innovate and stay ahead of the competition.

Grey Space Computing: Your Partner in Efficiency and Growth

At Grey Space Computing, we recognize the critical importance of efficiency and growth in today’s business landscape. That’s why we’re thrilled to introduce you to Oracle Integration Cloud Services (ICS) – a transformative solution designed to revolutionize the way businesses operate. Serving as a cornerstone in our mission to empower businesses with cutting-edge technology solutions, Oracle ICS seamlessly integrates applications, systems, and data sources to streamline processes and drive efficiency across the organization.

We understand the complexities of modern integration challenges and are committed to simplifying the process for our clients. With Oracle ICS’s intuitive drag-and-drop interface and extensive library of prebuilt integrations, our clients can effortlessly connect their systems and accelerate time to value.

Furthermore, Oracle ICS’s real-time monitoring and analytics capabilities provide invaluable insights into integration performance, enabling proactive problem-solving and optimization. Security is a top priority, with Oracle ICS implementing robust measures to ensure sensitive information remains protected.

The benefits of Oracle ICS extend far beyond efficiency gains. By reducing manual effort, increasing productivity, and facilitating cost savings, businesses can achieve improved efficiency, enhanced agility, and accelerated innovation.

FAQs

What is Oracle Integration Cloud Services (ICS)?

Oracle ICS is a cloud-based integration platform that facilitates seamless connectivity between various applications, systems, and data sources.

What are the key features of Oracle Integration Cloud Services?

Oracle ICS offers drag-and-drop integration, prebuilt integrations, real-time monitoring, and robust security features.

How can Oracle ICS benefit my business?

Oracle ICS can improve efficiency, enhance agility, reduce costs, and accelerate innovation within your organization.

How does Grey Space Computing support businesses in implementing Oracle ICS?

Grey Space Computing provides comprehensive support and expertise to help businesses seamlessly implement and optimize Oracle ICS within their operations.

Conclusion:

Grey Space Computing is dedicated to helping businesses unlock efficiency and drive growth through Oracle Integration Cloud Services. With its comprehensive features, intuitive interface, and robust security, Oracle ICS provides the foundation for seamless integration and collaboration across the organization. Contact us today to learn how Grey Space Computing and Oracle ICS can propel your business forward.

#Oracle Integration Cloud Services benefits#How to use Oracle Integration Cloud#Oracle Cloud integration best practices#Oracle ICS for business growth#Streamlining processes with Oracle ICS#Oracle Integration Cloud for efficiency#Enhancing business operations with Oracle ICS#Oracle ICS real-time monitoring features#Cost savings with Oracle Integration Cloud#Oracle ICS for seamless application integration#Oracle ICS security and compliance features#Improving productivity with Oracle Cloud integration#Oracle Integration Cloud for digital transformation#Maximizing efficiency with Oracle ICS#Oracle ICS drag-and-drop integration

1 note

·

View note